Engineered for success

ITM is a global leader in the design, manufacture and distribution of undercarriage components and complete undercarriage solutions.

We have the experience and know-how to meet all our customers’ needs: whether they require assistance during the design stage or application in the field, service or technical support, our experts are always on hand to help our customers to develop new solutions and deliver innovation in their different fields. And we are at their side every minute of the day too, helping them in their work.

Thanks to our global network, we can deliver rapid solutions to meet our customers’ specific individual needs.

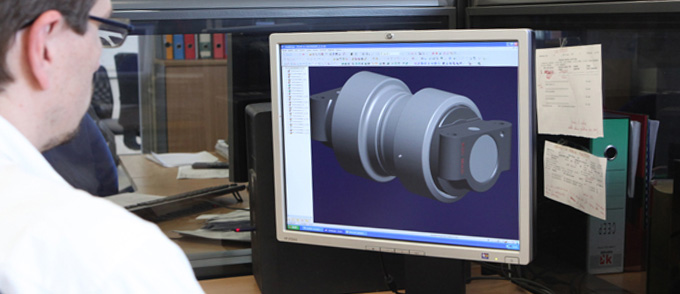

With nearly 40 experts working in our Engineering Centers, we can always satisfy the demands of our customers’ most challenging projects and develop innovative undercarriage solutions for them, whatever the application they need, wherever they are in the world.

We supply components to the leading OEMs on the market and our products are also available in the aftermarket through a global network of dealers and distributors.

Furthermore, since our production facilities and distribution network are so widespread, we are able to supply our products and spare parts quickly and efficiently.

Our team of Product Support Specialists can provide dedicated, high quality services and assist our customers, wherever they are, in record time.

Our global presence means we can draw on a vast and varied pool of expertise and experience, which everyone in the Group can benefit from.

Italtractor ITM SpA

This is the headquarters of the Group, from where we coordinate and control all our business activities, carry out R&D work on undercarriage components, innovative technologies for processes, personnel, information technology and controlling activities for the entire Group.

Our engineering team has acquired great expertise from years of collaboration with the major OEMs in the market and today adopts advanced technologies for the design, engineering and development of innovative undercarriage components and solutions, both for standard and special applications.

At all the three plants in Ceprano, Potenza and Fanano, we have adopted advanced production technologies and employ a specialized team for the production of our complete range of rollers and chains, with and without track shoes, for machines of all sizes up to those employed in the mining industry.

Titan Intertractor GmbH

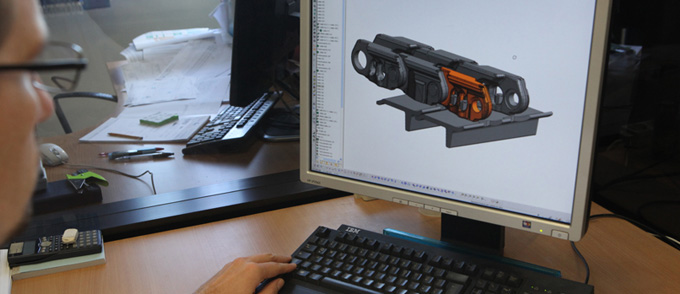

Titan Intertractor is the Group’s center of excellence for the design, engineering and assembly of complete undercarriages and side frames.

Our engineers have extensive know-how and long experience that allow them to design and develop innovative system solutions that meet every specific application requested by customers in the construction, mining, drilling, road building, agricultural sectors and special application sectors.

Equipped with the most advanced technologies, our team is now involved in the development of highly specialized applications for the mining and marine industries.

In our plant, undercarriages for cranes, planers, milling machines, drilling rigs and special track-mounted vehicles of any kind with operating weights of up to 2,500 tons are assembled by our experienced team.

Titan Intertractor is also the hub for the daily business aftermarket sales service in northern Europe.

Pyrsa Piezas y Rodajes S.A.

PYRSA is Spain’s largest steel foundry where we produce our complete range of idlers, sprockets and the new series of monobloc track chains for the mining industry.

The excellence of our pouring systems, the quality control procedures on the steel we use and the molding sand process, are based on the latest available technologies and allow us to reproduce all the stages of the industrial casting process.

We also run the following divisions at Pyrsa: heat treatments, mechanical machining, assembly and painting. This allows us to guarantee our customers total control of all quality parameters in a lean manufacturing process.

Thanks to our expertise and ability to rapidly respond to market demands, we have been present in the rail transport sector since 2005. And Pyrsa is the ‘preferred supplier’ of one the world's largest manufacturers of railway brakes.

Intertractor America Corp.

Intertractor America, the Group’s base in the United States, supplies complete undercarriage solutions, designed specifically for the construction, mining, crushing, drilling, forestry, road building and agricultural industries. Intertractor America also distributes undercarriage components to the North American aftermarket.

At this plant, we produce our standard and special track shoes, obtained from over 35 different profiles. Our production team has the required know-how for achieving process optimization.

From shoes for customized applications to highly innovative undercarriage solutions, our R&D team plays a key role inside our company and creates value for our customers by designing a vast range of products for special applications and to specific customer requirements.

ITM Latin America Ltda

ITM Latin America is the Group’s South American base, manufacturing rollers and track chains in a complete production process. Based in Brazil, over the years ITM Latin America has gained recognition in the market and is currently the leader in the aftermarket and OEM segments, providing products throughout Latin America.

Our flexibility in meeting market demand is due to the fact that we provide a complete manufacturing process within the company, including forging, heat treatment, machining, assembly and painting. Our Engineering Department works tirelessly to make our process more competitive, while maintaining our high quality standards.

We produce a wide range of products and, as a result, are one of the key players in sectors such as forestry, mining, crushing, road building and agriculture. Thanks to our team of highly experienced employees, ITM Brazil is the ideal partner for any business.

Titan ITM (Tianjin) Co. Ltd

Titan ITM Tianjin is the Group’s base in China for the manufacturing, assembly and supply of undercarriage components and undercarriage side frames to the local market.

Our factory employs state-of-the-art production technologies to produce and assemble track chains, rollers and idlers for standard and special application crawler machines used in the construction and mining industries, including the most popular 6-50 ton excavators.

Thanks to the engineering expertise provided by the Group’s centralized team of engineers, we are able to supply customized side frames for paving, road milling and other special machines to local OEMs.

Our teams of quality experts ensure that our products comply with exacting international standards.

ITM mining pty Ltd

ITM Mining is the base for ITM’s operations in Australia. Two modern facilities, located in Western Australia and Queensland, ensures coverage to major Australian mining regions, offering on-site and service repair as well as plenty of stock.

In addition to track shoe regrousing and components re-shelling / rebuilding, ITM offers a complete frame refurbishment program.

All the service are carried out by our expert personnel, with a long experience in undercarriage maintenance.